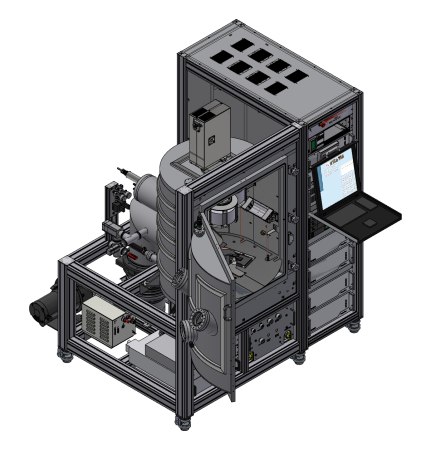

P365 – 17″ HV E-Beam deposition TopTec

Application

HV E-Beam deposition system for thin film and multilayer deposition at 17″ substrates

Year of delivery

2013

Installation site

TopTec, Turnov, Czech Republic

Design Features

- HV E-Beam deposition system in combination with ion beam assisted deposition and thermal evaporation sources.

- Two multi pocket e-beam sources.

- Motorized pocket exchange for automatic deposition processes.

- Pneumatic source shutter to avoid deposition during material heat up time.

- Thickness controller incl. rate regulation and end point detection.

- Thickness sensor with temperature observation for improved reproducibility.

- Two thermal evaporation sources.

- Pneumatic source shutter to avoid deposition during material heat up time.

- Sample manipulator with motorized sample rotation and maximal sample temperature above 300°C.

- Ion source for sample precleaning, mild etching, plasma treatment and ion beam assisted deposition (IBAD).

Special Features

- System integration in clean room wall (door and user interface is in clean room; rest of the sytem is in gray room).

- Sample manipulator can be equipped with at least two different stage heads.

- Stage head 1 for one samples with diameter of max. 450mm (max. 25kg).

- Stage head 2 for three samples with diameter of max. 200mm diameter.

Outer Dimensions

Technical specifications and performance values

General

E-Beam chamber

Size

About 750 mm width, about 900 mm depth, about 900 mm height (D-shape chamber with door)

Material

stainless steel

Vacuum

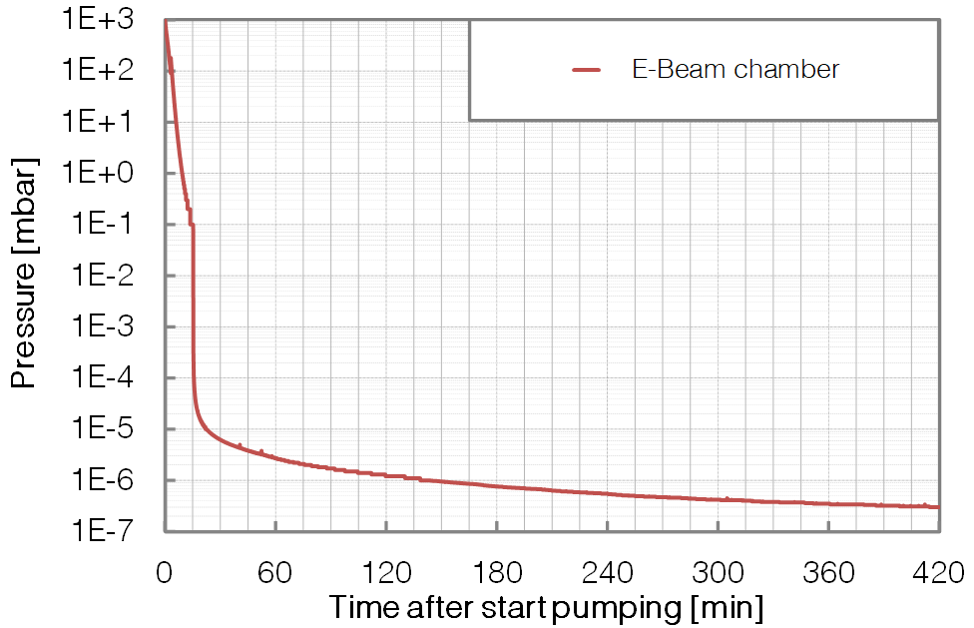

E-Beam chamber

Base pressure

< 2 *10-7 mbar

Pump down time

4.5 hours to < 5 *10-7 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

E-Beam chamber

Sample size

Sample stage head 1: diameter max. 450 mm substrate (max. 25kg)

Sample stage head 2: three samples with diameter max. 200 mm substrate

Motion axes

Sample stage head 1: motorized (continous) sample stage rotation

Sample stage head 2: motorized (continous) sample stage rotation incl. planetary rotation at each sample

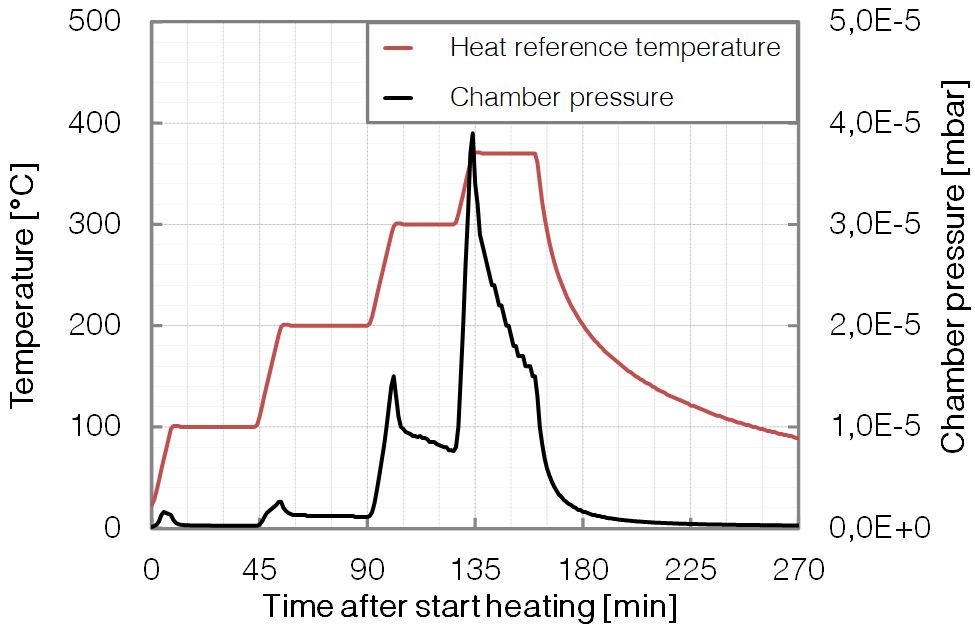

Temperatures

Room temperature (not stabilized) up to 300°C at sample

Sample preparation features

E-Beam chamber

Plasma treatment

Up to 5E-4 mbar partly ionised argon gas (using a griddless ion gun)

Ion beam etching /

sample precleaning

Wide range variation of ion energy and ion beam current