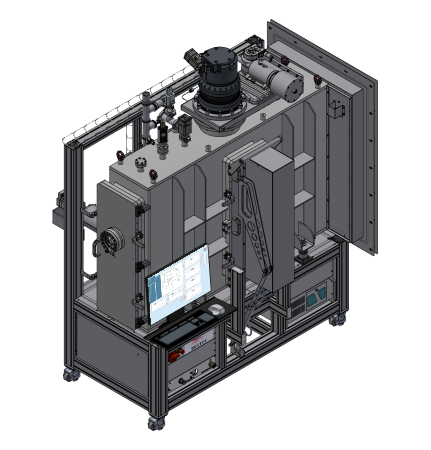

P498 – HV sputter deposition Nanocomp

Application

HV inline sputter deposition system for thin film deposition at special sized substrates

Year of delivery

2022

Installation site

Nanocomp Oy Ltd, Lehmo, Finland

Design Features

- Inline HV magnetron sputter deposition system with full automatic control system.

- One 28″ x 3.5″ rectangular magnetron in face to face configuration.

- Magnetron mounted at a flipping door for fast and easy target exchange and source cleaning.

- Direct gas inlet close to the target installed at each magnetron.

- Pneumatic driven source shutter.

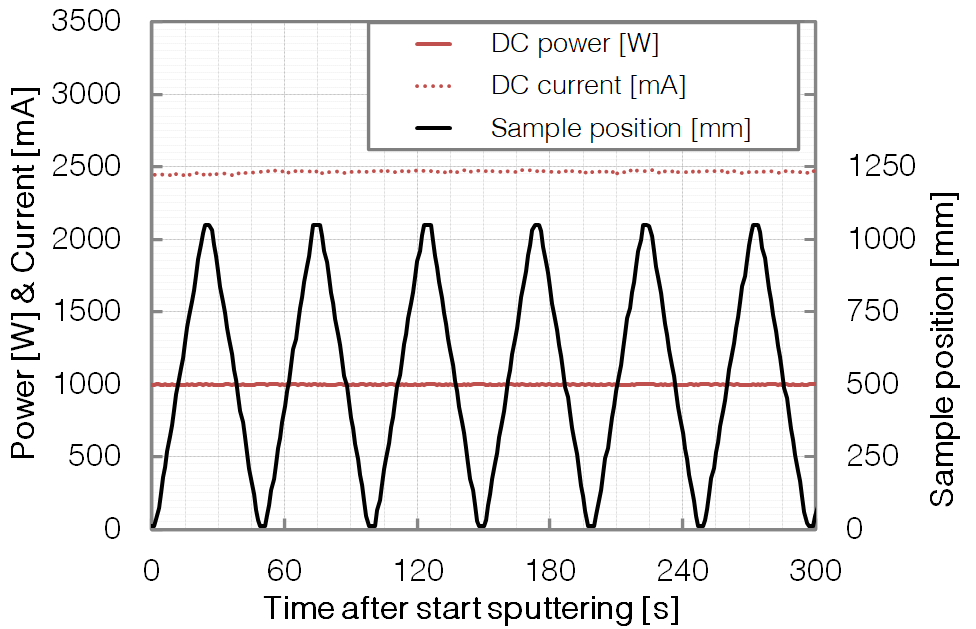

- Motorized sample trolley with variable constant speed motion mode.

- Wobbling motion in front of the magnetron possible.

- Maximal sample size of 508mm x 508mm x 5mm.

- Three big system access doors.

- One towards clean room for sample loading and unloading.

- One towards gray room for easy service access mainly.

- One for service at the sputter soruce or deposition region of the system.

- Software controlled upstream pressure regulation system.

Special Features

- Large motion speed range from < 0.1 mm/s up to > 50mm/s possible.

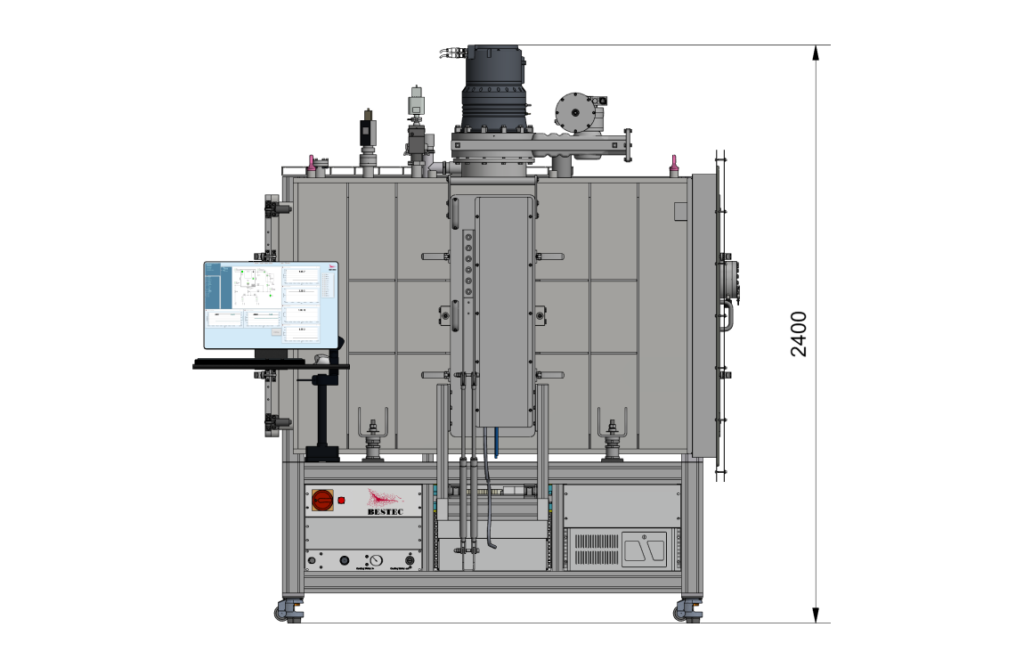

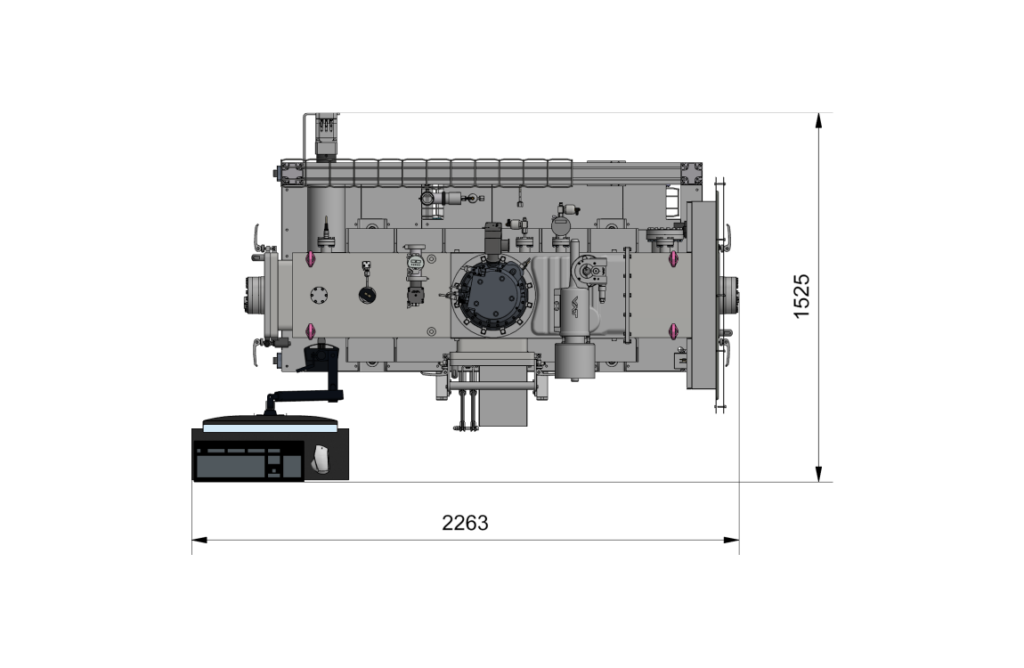

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

Cubic shape chamber, about 2000 mm length, about 650 mm width & about 1500 mm height

Material

stainless steel

Vacuum

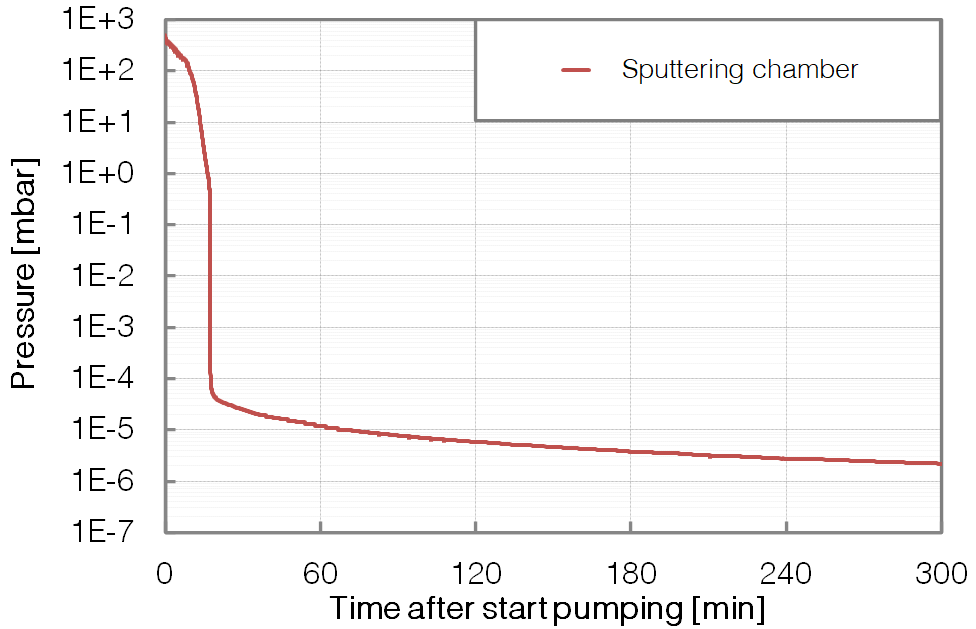

Sputtering chamber

Base pressure

< 3 *10-7 mbar

Pump down time

10 hours to < 10-6 mbar

Chamber pumping

Turbo pumping stage with dry foreline pump

Manipulator features

Sputtering chamber

Sample size

max. 508mm x 508mm x 5mm special shaped samples

Motion axes

Motorized sample translation axis with motion speed range of min. 0.1 mm/s up to max. 50 mm/s, incl. sample position wobbling feature