P499 – 6″ HV E-beam deposition IPHT

Application

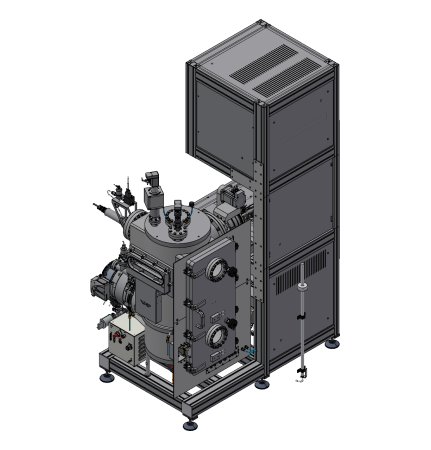

HV e-beam deposition module (prepared for cluster integration) for thin film and multilayer deposition at 6″ substrates

Year of delivery

2022

Installation site

Leibnitz IPHT, Jena, Germany

Design Features

- HV E-Beam deposition system in combination with ion beam sample treatment.

- One multi pocket e-beam source.

- Motorized pocket exchange for automatic deposition processes.

- Pneumatic source shutter to avoid deposition during material heat up time.

- Thickness controller incl. rate regulation and end point detection.

- Sample manipulator with two motorized axes (stage tilt and sample clamping) and sample cooling.

- Ion source for sample precleaning, mild etching and plasma treatment.

Special Features

- System is prepared to be added to a cluster tool via SEMI standard transfer port.

- Different sample sizes from 6″ wafer down to 3″ wafer can be handled (using different kind of sample adapters).

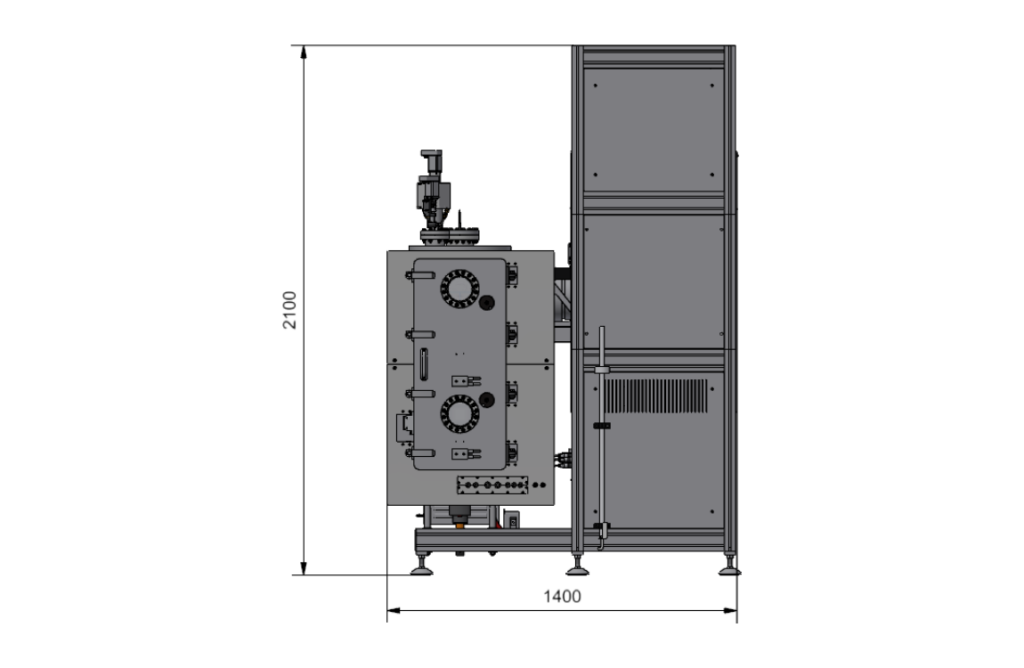

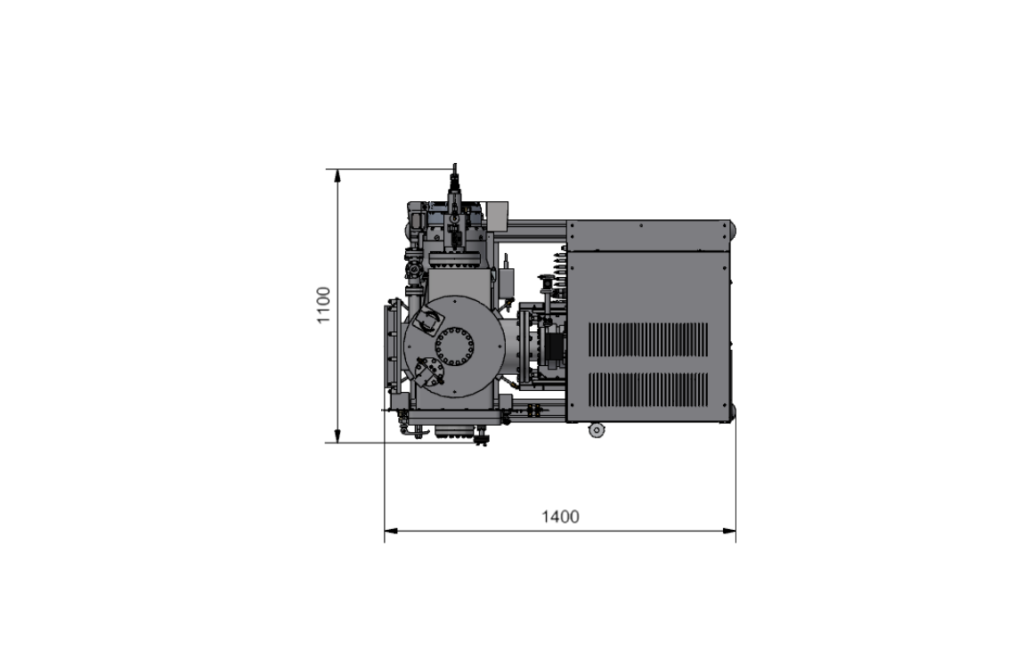

Outer Dimensions

Technical specifications and performance values

General

Deposition chamber

Size

About 500 mm width, about 590 mm depth, about 910 mm height (D-shape chamber with door)

Material

stainless steel

Vacuum

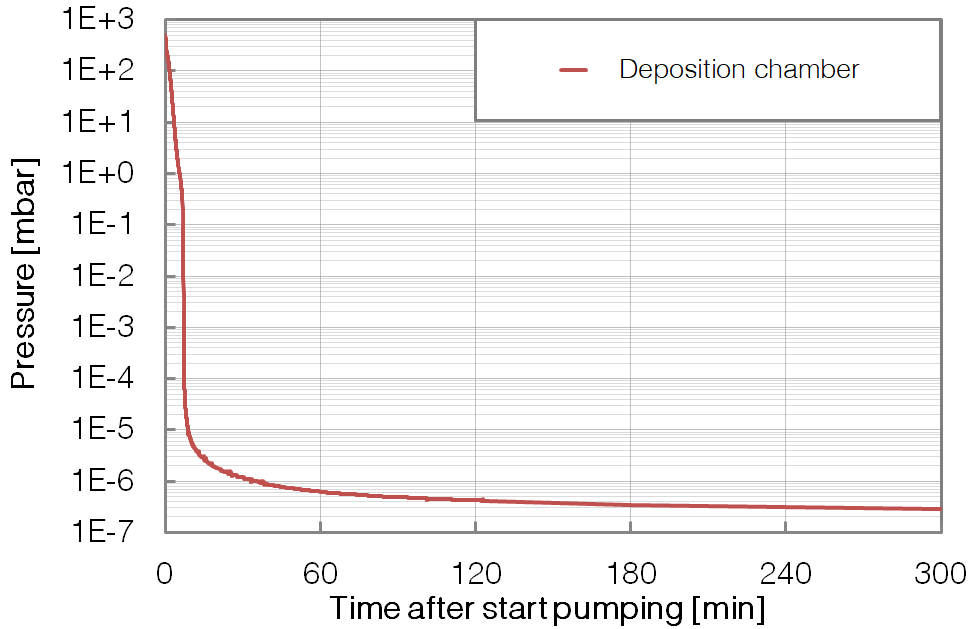

Deposition chamber

Base pressure

< 1 * 10-7 mbar

Pump down time

5 hours to < 2 * 10-7 mbar

Chamber pumping

Turbo pumping stage, chamber door differentially pumped by dry foreline pump

Manipulator features

Deposition chamber

Sample size

diameter max. 6″ substrate

Motion axes

2 motorized axes (manipulator tilt rotation and sample clamping stage)

Motor driven (rotating) sample shutter with wedge shutter feature

Temperatures

About 15°C to 25°C (sample cooling without temperature control)

Sample preparation features

Deposition chamber

Plasma treatment

Up to 5E-4 mbar partly ionised argon gas (using a griddless ion gun)

Ion beam etching /

sample precleaning

Wide range variation of ion source to sample distance

Wide range variation of ion energy and ion beam current